In the realm of construction, the choice between steel and concrete as the primary building material has

A great deal of what has been published with regard to the steel industry in recent years, relates to the

The technologies for achieving climate-neutral steelmaking are available right now. They are ready to be

Dust and particulate matter emissions were reduced to under 3mg/Nm3 and heavy metals were reduced by 80%

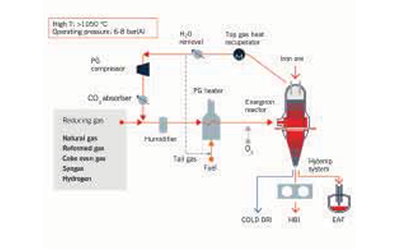

The decarbonization of the steel industry depends on eliminating fossil fuels throughout steelmaking

AUMUND Fördertechnik is supplying two bucket apron conveyors for transporting hot direct reduced iron

Today’s steel producers face immense challenges when working with an electric arc furnace (EAF). These

Dry blast furnace gas cleaning technology offers great economic advantages when compared with traditional

In 2015 voestalpine decided to invest in a new benchmark slab caster to replace the existing CC3 caster,

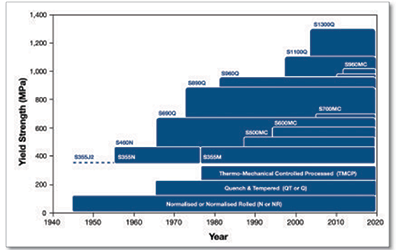

The steel industry continuously strives for progress, focusing on innovation to streamline operations,

cunova GmbH, formerly known as KME Special Products and Solutions GmbH,based in Osnabrück, is a leading

This paper introduces the Quaker Houghton Pilot Mill and its capabilities.We demonstrate how a rolling

Unforeseen shear blade changes in a continuously running strip processing line, causes production downtime

High-performance production of innovative laser cut and welded products and the presentation of a unique

Sarclad and CRM Group have successfully developed a new on-ine sensor for steel strip contamination. The

Along with hydraulic presses, manipulators are the key components of any forging operation. Unplanned

Steel is fundamental to many industries and is essential for economic development, from automation to

The transition from an integrated to an electric steel process route, results in differences in the steel

The digital revolution and sustainable development are two megatrends thatwill impact and transform

AIC Group is an international company based in Italy and Germany with subsidiaries in several locations.

This article presents the Through-Process Quality Control (TPQC) System and Through-Process Optimization

With high-grade iron ore demand increasing, the availability and cost of low-grade iron ore reveals an

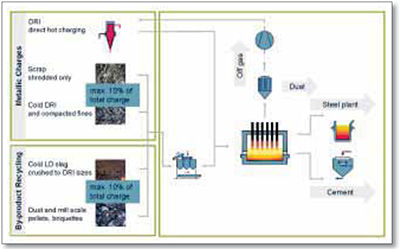

The green steel revolution is progressively shifting crude steelproduction from BF-BOF technology to

Despite the fact that the price of scrap is usually higher than that of hot metal, environmental

The production of iron pellets results in the emissions of NOx. This paper describes the application of

By replacing steam ejectors with mechanical vacuum pumps, steel plants can release steam production that

Direct reduction based on natural gas or hydrogen offers considerable emission reduction potential, as

As an international supplier of specialist conveying solutions for metallurgical processes in the iron and

The Digimelter® represents a technological breakthrough in electric steelmaking, with lower power and

Since the startup of Danieli Converter Technology in 2011, several BOF revamping projects have been

Success in the wire rod market can only be achieved by combining high plant productivity, efficiency and

Atomat has developed the Giana AT925E multifunctional CNC lathe. It has a solid design to ensure

Investing in sustainability, the environment and safety are high on the agenda in the steel industry

NCO automatic motorized rest bars for rolling guides in hot rolling mills: automation, precision and

Nuova Carpenteria Odolese (NCO) has developed automatic, motorized rest bars for rolling guides in Hot

The hot gunning repair of refractories for converters, ladles, EAFs, RH-snorkels, etc., is a cost saving

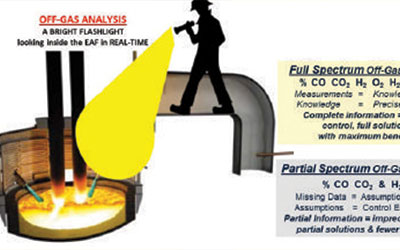

This paper discusses Tenova’s ‘Intelligent EAF’ solution, provides actual plant results confi rming

The potential for full automation of the Electric Arc Furnace (EAF) is explored in this paper, by means of

Reducing reheating furnace gas consumption and the billet head-tail temperature differential for bar

Nuova Carpenteria Odolese (NCO) have developed and commissioned an insulated roller table/billet reject

As a part of the modernization of the Oxelösund Blast Furnace No. 4 hot blast system, SSAB and Danieli

Dango & Dienenthal (D&D) have developed a parallel lifting-lever technology, that has been

A great deal of what is published and announced in recent years states and explains the need to

As global crude steel production steadily increases towards the two billion tonnes mark, it remains one of

Energy efficiency improvements resulting from oxyfuel combustion, with fossil fuel savings of 20% to 60%,

The steel industry is integral to the global circular economy and thus to the successful delivery and

The majority of steel produced around the world today comes from the primary Blast Furnace-Basic Oxygen

Steel, with its high strength-to-weight ratio, recyclability and relatively low production costs, will

Waste heat generated from the steel production process is extracted to produce power through waste heat

SCHADE Lagertechnik has been operating since 1879 and is internationally renowned for the design and

The environmental footprint of the production of iron and steel is well known by the industry and in

Germany and the European Union aim to be CO2 neutral by 2050. At the same time, there is shortterm

The steel melting process in an electric arc furnace (EAF) is a complex set of tasks, coping with highly

Mechanical vacuum pump systems are state-of-the-art technology for new refining stations, having well

Hardly any material has influenced world economic development to such an extent as steel. It not only

Ergolines has developed a new system (UT-MAP) based on contactless ultrasonic technology for real time

In the future, there will be a growing demand for green steel produced using renewable energy. This demand

Today’s leading steel and aluminum rolling mills need to consistently produce high quality textured

Laser diameter gauges have already been in use in long products rolling mills for more than 40 years.

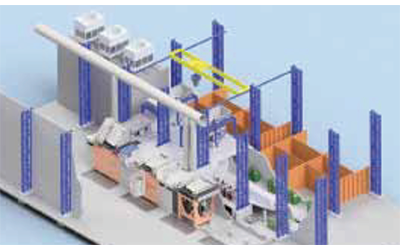

AIC Group has developed an ambitious mechanical system, AIC TrimBot, using both vision technology and

Management of the scrap and metal yard is one of the most fundamental processes in steelmaking, in terms

Reducing CO2 emissions with the aid of machine learning: digital solutions to enable climate neutral

Whether in politics, civil society or business, there is agreement that industry must become greener, yet

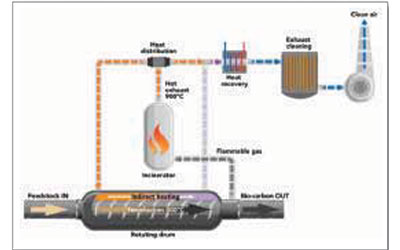

Heat treatment processes are becoming increasingly complex; the variety of products and formulas is

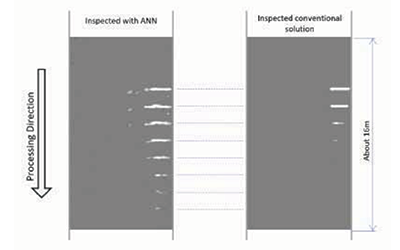

Breakthrough in Detection and classification of Surface Inspection Systems (SIAS®) via deep learning

Surface inspection has been part of the high technology landscape of the steel industry for three decades.

The current production process for galvanizing entails pulling a preheated plate of steel through a

In recent years, automation of CNC machine tools has been focused on the exclusion of human intervention